Winch bumper fabrication

Google Sketch-up drawing (download here)

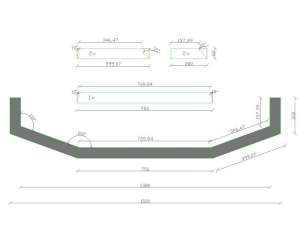

Bumper design made in AutoCAD (download here)

The build

I clamped the bumper to some box section, the box section is the same as i used on the body-lift so it's between the body mounts on the chassis and the body

And this is the metal version, it's 6mm thick, a few tag welds will keep it in place until i take the bumper of the car again

Since i'm building a decent bumper i might as well make some solid recovery points out of 12mm steel

Both sides done, now you don't have to reach down in to the mud looking for the stock recovery point

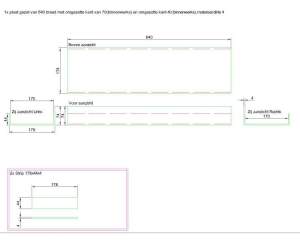

Winch-plate design made in AutoCAD (download here)

Opening for the fairlead, for the hawse and roller version, i will be using the wire-rope first, but after it wear's out i will buy some dynema

I'm not happy with the height of the push-bar which will be bolted to the winch-place, it should be a little lower

45mm removed of the bracket, the winch-plate will rest on the bracket to (will also be welded to it)

Took the bumper of the car for some easy acces while welding and drilled some holes to drain the water from the winch-plate

Added a piece of angle iron for extra strength on the rear bolts of the winch (torsion of the winch drum under heavy loads can bend metal)

Improvements

After extreme winching i lost all onboard power in the car, the alternator wanted to charge the battery with a high current which blew the "fuseable link" a piece of wire which act's like a fuse, but who has a spare for that in his car ?

I replace the "fuseable link" with some 6mm² wire and added a 40amp Maxi-fuse, also disconnected the charge wire from the alternator from the stock wiring loom and replace it with a 16mm² wire with a 80amp Maxi-fuse direct from the alternator the the battery